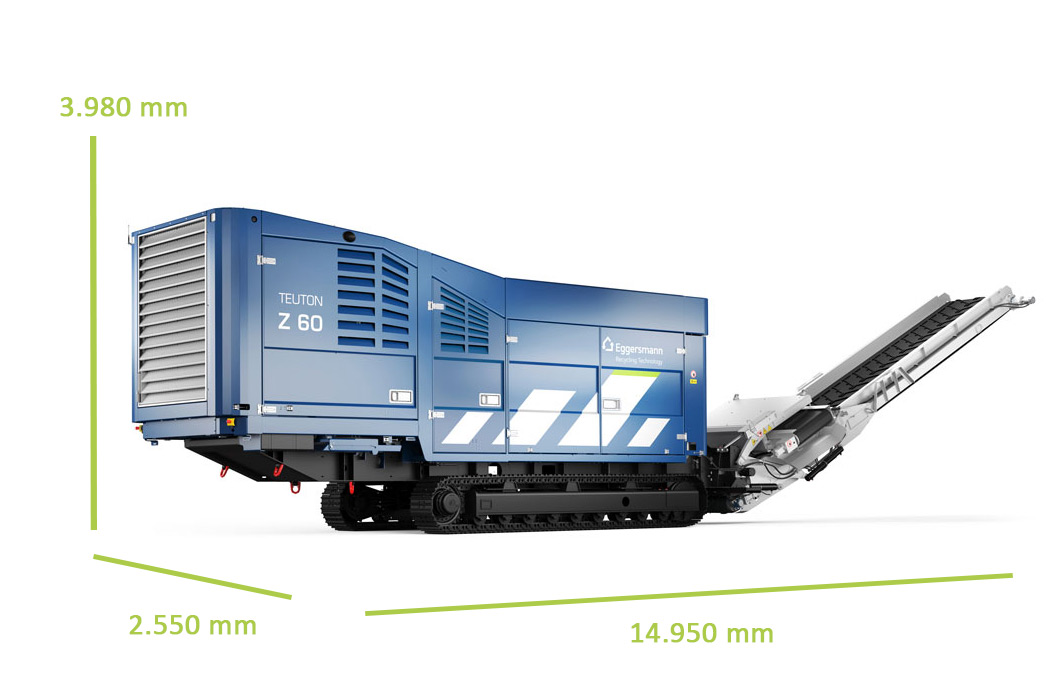

TEUTON Z 60

The Heavy Duty Shredder for Extra Large Quantities

Product Highlights

- Easily exchangeable and robust rotor tools with double screw connection

- Durable "Marathon" shredding rotor (disruptive resistant)

- Perfect material feed due to 4.5 m wide feed area

- Tool-free cutting gap adjustment in six stages

- Large selection of shredding tools, even for the most difficult applications

- Optional screen basket system for marketable end products

Technical Highlights

- Power: 447 kW (600 PS)

- Throughput: up to 120 t/h

- Weight: 32,000 kg / 34.000 kg

Our Eggersmann TEUTON Z 60 is even bigger and even more powerful in its workmanship. Consequently, even the most stubborn material succumbs to its 600 hp rotor. At the same time, the TEUTON Z 60 enables unprecedented precision in defining the final grain: Not only does it have eleven different cutting gap settings, but all four different rotor train settings can be freely combined with the two different screen basket systems in their respective hole and gap sizes. Maximum performance and maximum precision – that is the TEUTON Z 60.

What Versions and Drives are Available?

Track

Semi-Trailer

Diesel-Hydraulic

Your Contact

- Low-speed universal shredder

- Shredding for almost any application

- Throughput up to 120 t/h

Applications

Waste wood processing

Waste wood categories A 1 to A 4

Processing green waste

Composting green waste

Processing of bulky waste

Shredding bulky material

Downloads

Shredding

Transform your Waste

Contact Persons

Our expert team will be happy to advise you!

Robert Skalei

Service Coordinator Shredding Technology

TEUTON | FORUS

Mobile Machines

Fon +49 800 EGGERSMANN

Fon +49 800 3443776

teuton-service(at)f-e.de