Eggersmann Recycling Technology

Highest composting qualities

and reduced screen residues with the Eggersmann fine processing technology. Impurities are efficiently removed at several suitable points in the treatment process with perfected separation and sorting technology. Thus, a final product nearly free of impurities is created.

- High compost yield

- Reduction of screening residue

- Best possible removal of impurities

- Throughput of the entire plant possible up to 100 m³/h.

- Reduced disposal costs

- Highest process reliability even with different moisture contents of the material.

Coarse Screen

STAR SELECT SC

- With the STAR SELECT coarse screen technology, larger lightweight material and other oversized material is mechanically removed in the first step

- On request, the screen cut can quickly and easily be adjusted by changing the rotational speed of the screen shaft

- If required, the lightweight material can already be sieved from the screen overflow at this point with the Eggersmann AIRFIX air separation technology

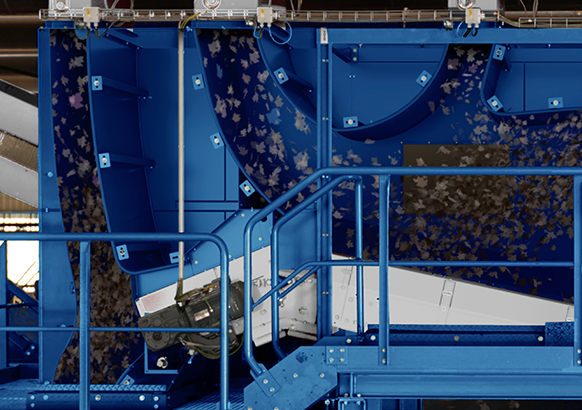

Fine Screen

STAR SELECT SF

- Screening of the fine compost is done with the Eggersmann STAR SELECT fine screen technology

- In order to best prepare the contaminated medium fraction for subsequent removal of impurities, the individual screen shafts operate with the new patent-pending Eggersmann Split-Speed method

- The rotational speed of the screen shafts is adjusted variably and independently from each other to ideally position the undesired light material on the material stream during the screening process so they can be reliably suctioned off with the AIRFIX air separator

- Subsequently, the medium fraction, freed of impurities, is returned to the composting process

- The fine fraction (grain size ≤ 15 mm) is fed in thin layers to the multi-step wind sifter, the CO2MPOST CLEANER

More and more plastic in the compost

The bio waste delivered to biological waste treatment plants is often contaminated with high shares of impurities such as glass, metal or plastic. These substances can only be removed to a certain extent with conventional treatment technology before and after the biological treatment step. Despite a reduction of the screen cut in the compost treatment to 10 mm for instance, too many foreign particles remain in the compost product. Especially the share of plastics creates more and more problems for plant operators, in particular with regard to increased requirements of the compost users in connection with the discussion about microplastics in the soil.

According to the exacerbated specifications, the produced compost can only be applied onto soil, if a certain amount of impurities is not exceeded. For example, the German bio waste ordinance stipulates a limitation of max. 0.4 % (with regard to the dry matter to be applied) of glass, metal and malleable plastic and max. 0.1 % of other plastics.

Eggersmann compost fine processing

The reduction of the screen cut lessens the compost yield (recovery quota) and simultaneously increases the amount of costly disposal of screening residue, which is mostly contaminated with large and flat plastic.

This is exactly where the Eggersmann fine treatment plants come into effect. Impurities are efficiently removed at several suitable points in the treatment process with perfected separation and sorting technology. Thus, a final product nearly free of impurities is created. Additionally, the marketing opportunities for cleaned screening residue as fuel is improved. As an alternative, screening residue which is freed from foils can easily be returned to the composting process.

You are planning to modernize your biological waste treatment plant?

Contact us now, we will gladly advise you! No matter if you are looking for a new construction, a process optimization or a retrofit of your plant - we are your competent partner!

To sieve out undesired heavy matter,

the contaminated compost in the CO2MPOST CLEANER gets blown with air during material inlet. The different flight and sink characteristics due to the cW value and density as well as the ballistic effect when hitting the arch belt ensure effective separation of heavy parts from the material stream. They fall down. The arch belt transfers the light and moderately heavy material to the separation chamber.

The airworthy and conveyable light material

is deflected way above the arch belt. Subsequently, the light matter passes two further separation points where the light material (primarily foils and fibrous material) is suctioned off by the air stream.

The remaining material after the second separation point

is guided into a chute. The heavy, grainy material particles fall down and form a nearly impurity-free compost fine fraction. The remaining light material gets sucked upwards via the air stream from underneath.

The material from all three light material separation points that was suctioned off is transferred to a light fraction separator. Foils, sheets and leaves are separated here. The pre-cleaned air, now only containing small particles, is fed into a bag filter for filtering. Part of the cleaned air is reintroduced into the process by means of a fan and the blowing nozzle. The rest is released into the environment.

The highly efficient Eggersmann exhaust air treatment guarantees lowest dust residue values < 5 mg/m³ which can be returned into the environment without hesitation or which can be fed into the rotting process if required.

Further Eggersmann methods for bio waste treatment:

Eggersmann treatment technology - the comprehensive, forward-thinking solution for the treatment of biological waste, with the goal of optimal use of the energy and resource potential within the waste.

Pretreatment

Residual waste, commercial waste or presorted packaging waste - they all contain raw materials which can be made available again by mechanical processing. Different separation equipment is used in sorting to separate the desired materials.

Rotting tunnel

Aerobic treatment of organic material in the rotting tunnel. The tunnels offer a wide variety of applications depending on the input substrate and treatment goal. Furthermore, the tunnel can be equipped with a heat exchanger, insulation and a ventilation system, according to the specific requirements.

BEKON dry fermentation

The BEKON dry fermentation accomplishes a high and constant production of biogas by fermenting solid substrates (for example bio waste, garden waste, organic fractions from residual waste treatment, solid cow dung and other stackable organic waste).

You would like to improve the quality of your compost?

Contact us today for a consultation! We have the answer for growing quality requirements!

Downloads

Eggersmann compost fine processing

Windrow Turner & Lane Turner

Contact Form

Contact

Contact us now! We will be happy to advise you.

Björn Bischoff

Sales Director

Eggersmann GmbH

mobile machines

Do you already know our other campaigns?

Get an overview of the versatile range of application of our machines now.