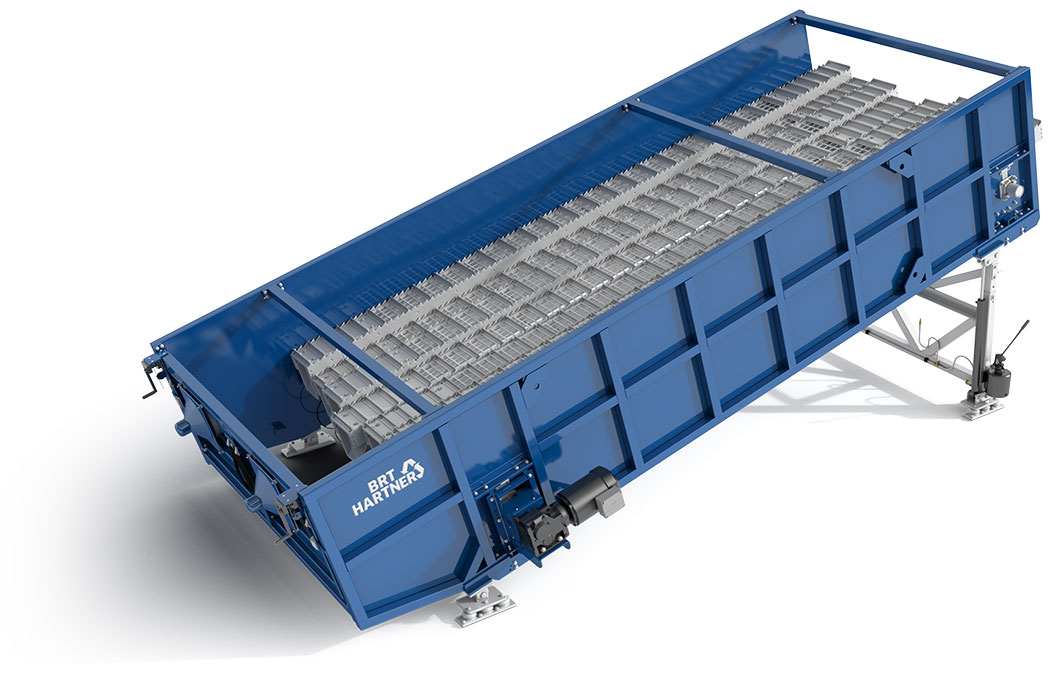

Ballistic Separator BRT HARTNER BS

Ballistic Classifier for the Separation of Several Fractions of Packaging Waste, Household Waste, Commercial Waste and Mixed Construction Waste

The Ballistic Separator BRT HARTNER BS is the best choice for an effective sorting process at low cost and with high availability.

It separates the material into three fractions. The separation process is done in just one step. The movement of the paddles sets the infeed material into vibration for a vertical as well as a horizontal conveying direction. The vertical acceleration mixes the material thoroughly which leads to excellent separation and yields a high screening quality.

The BS Ballistic Separator separates the material based on the climbing ability and the irregular ballistic behavior of the components. Rolling and bulky objects, stones, bottles and other hollow bodies submit to the ballistic principle and travel to the lower end of the machine (3D) where they are discharged. Lightweight and flat material, foils, textiles and paper migrate upward, subject to their individual climbing ability, to the overflow at the upper end of the machine (2D). During this process, the lightweight matter is hurled up repeatedly. By the time the matter lands on the screen, most of the fine debris clinging to it (such as moist soil or dust) will have been removed. A third fraction is achieved as a sieve fraction by the perforation of the sieve on the paddles. The size of the sieve grid can be chosen according to the material.

The conveying speed, the ballistic separation and the level of material mixing can be adjusted by modifying the rotational speed. A separation precision of up to 90% can be achieved with the BRT HARTNER Ballistic Separator.

The Ballistic Separator persuades with its sturdy machine design for continuous operation, with its wide variety for different types of application and with its special bearing. These bearings are exchangeable without dismounting of the shaft. A high-maintenance crankshaft is not necessary. The shock-absorber-system for each paddle and the central lubrication system complete this ballistic classifier. It is available in different construction designs, variable widths and lengths and with several types of additional equipment.

The machine is driven by an electric gear motor. The corresponding frequency converter is also supplied. The transfer of the torque onto the crankshaft at the output side is done by the paddles. The sieve grids are easily exchangeable. Maintenance of the ballistic classifier is made easy by maintenance openings which are secured with safety door switches.

Andre Berlage

Executive Manager

BRT HARTNER

Stationary Machines

Fon +49 5451 50773-31

Cell +49 160 90693161

a.berlage(at)f-e.de

All Technical Data in section Downloads.

- Sturdy and solid design of the Ballistic Separator

- Separation into three fractions done in one step

- High separation quality

- Numerous parameter settings

- Dedusting and cleaning of lightweight fraction from fine debris and adhesions

- Optimal separation result with different materials

- Maintenance-friendly bearings and shafts

- Exchangeable sieve grids on the paddles

- Easy and direct drive system

Downloads

Opening, Dosing & Sorting Systems

Transform your Waste

Contact

For further information about the Ballistic Separator BRT HARTNER BS please get in touch with your personal contact:

Andre Berlage

Executive Manager

BRT HARTNER

Stationary Machines

Fon +49 5451 50773-31

Cell +49 160 90693161

a.berlage(at)f-e.de

Steffen Simonsen

Area Sales Manager

BRT HARTNER

Stationary Machines

Fon +49 5451 50773-30

Cell +49 173 5319440

s.simonsen(at)f-e.de

Detlev Rakemann

Area Sales Manager

BRT HARTNER

Stationary Machines

Fon +49 5451 50773-51

Cell +49 170 2200649

d.rakemann(at)f-e.de

You are looking for a wind sifter for light and heavy separation? Then you are welcome to pay a visit to our stationary Air Belt Separator.